Laser Laser Advantage

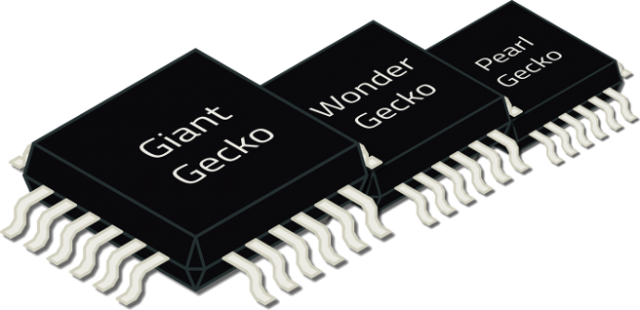

The text and pattern information on the chip has its corresponding representative meaning, which is convenient for later identification and tracking. However, the chip is characterized by its small size, high accuracy in marking positions, and can not destroy the functional properties of the chip. Therefore, laser marking is the best choice.

Laser marking is one of the most widely used laser processing techniques. According to the laser type, it can be divided into optical fiber laser marking machine, CO2 laser marking machine, semiconductor laser marking machine, etc.. The principle is to use a laser with high energy density to irradiate the workpiece locally, causing the surface material to vaporize or change color, leaving a lasting clear and indelible mark.

Laser marking is one of the most widely used laser processing techniques. According to the laser type, it can be divided into optical fiber laser marking machine, CO2 laser marking machine, semiconductor laser marking machine, etc.. The principle is to use a laser with high energy density to irradiate the workpiece locally, causing the surface material to vaporize or change color, leaving a lasting clear and indelible mark.

The text and pattern information on the chip has its corresponding representative meaning, which is convenient for later identification and tracking. However, the chip is characterized by its small size, high accuracy in marking positions, and can not destroy the functional properties of the chip. Therefore, laser marking is the best choice.

Laser marking conditions:

- Confirm laser selection to meet the requirements of workpiece quality and appearance.

- Design IC laser automatic marking system overall mechanical structure,

- Ensure accuracy of automatic calibration of IC chip laser

- The completed automatic marking system of IC chip laser is tested and tested jointly.

Select Puliming Laser Marking

- Reduce replacement costs and increase efficiency

- Fixtures can be quickly replaced to achieve multi-variety, small batch IC chip flexible production.

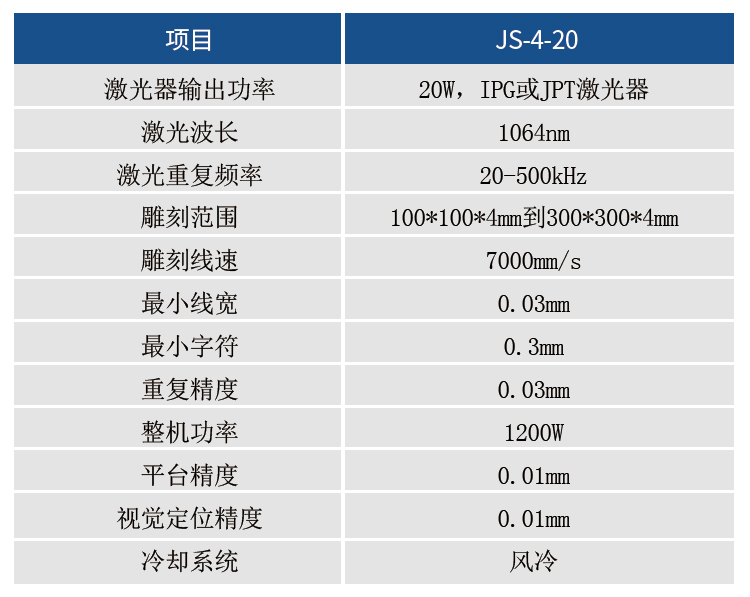

- Realization of high precision and high speed requirements for IC chip laser marking

- The operation of laser, image processing system and motion control system is integrated.

- According to different IC chip products, the optimized control parameters meet the requirements of equipment design and accuracy of IC chip laser marking.

- Due to the small area of IC, the location accuracy of marking is high(less than 0.05 mm), and it is suitable to use laser marking.

- Combined with electromechanical system design, multi-variety and small batch IC marking flexible production can be realized.